Case Study

SWCC / Marafiq / Saudi Archirodon

Yanbu II Power and Desalination Plant

Saudi Arabia

Project introduction

Hubert was awarded the contract for delivery of the marine package or seawater intake filtration system. Hubert was responsible for ensuring that the specification was met for all deliveries in subcontracting.

Hubert Supply

This project involved the construction of the complete seawater intake filtration system, consisting of 4 chanels or intake ‘trains’.

The seawater intake filtration system is designed to remove completely sea grass / weed, debris, plastic bags, wood chip, mollusk, jelly fish etc.

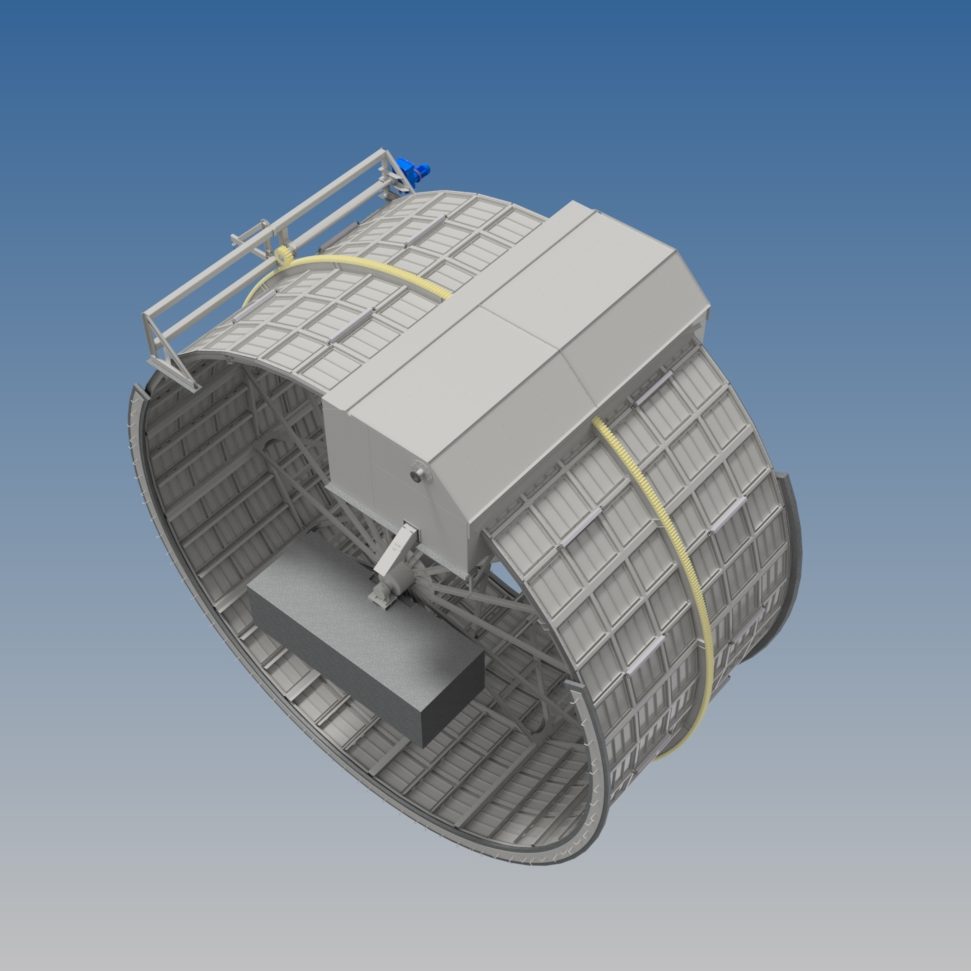

The 4 delivered Hubert drum screens have a diameter of 13 m and a width of 6,6 and have a capacity of 110.000 m3/h. Hubert bar screens are used to keep out large parts. Bar screens will be periodic cleaned by an automatic raking system, placed on a monorail construction.

Hubert stoplogs permit rapid and secure closure of very large inlet chanels and pump chambers, to make periodic inspection and maintenance of screening systems and pumps possible.

Hubert was also responsible for supply of the spray water system, the cathodic protection facility and project-related E&I work.

In 2015 Hubert supplied to the Yanbu III project 10 drum screens with diameter 11 m x width 6,2 m in s.s. 316, capacity 123.800 m3/h

Key Figures

- Location: Yanbu region, Saudi Arabia

- Hubert products: vertical drum screens, stoplogs, coarse screens and monorail raking system

- Materials: duplex

- Year: 2013