Rotary Drum Filters: Effective Filtration for Wastewater Applications

Utilizing rotary drum filters for efficient water and wastewater filtration solutions

When it comes to water intake systems and wastewater treatment plants, choosing the right filtration equipment is crucial for efficient and cost-effective operation. One of the most reliable and versatile options available today is the rotary drum filter.

In this article, we will explore the key features, benefits, and applications of rotary drum filters, including their wear resistance, high filtration performance, and low operating costs. As a leading supplier of screening machinery for water intake systems and equipment for wastewater treatment, we at Hubert are proud to offer a wide range of high-quality rotary drum filters to meet the needs of our customers.

What are rotary drum filters?

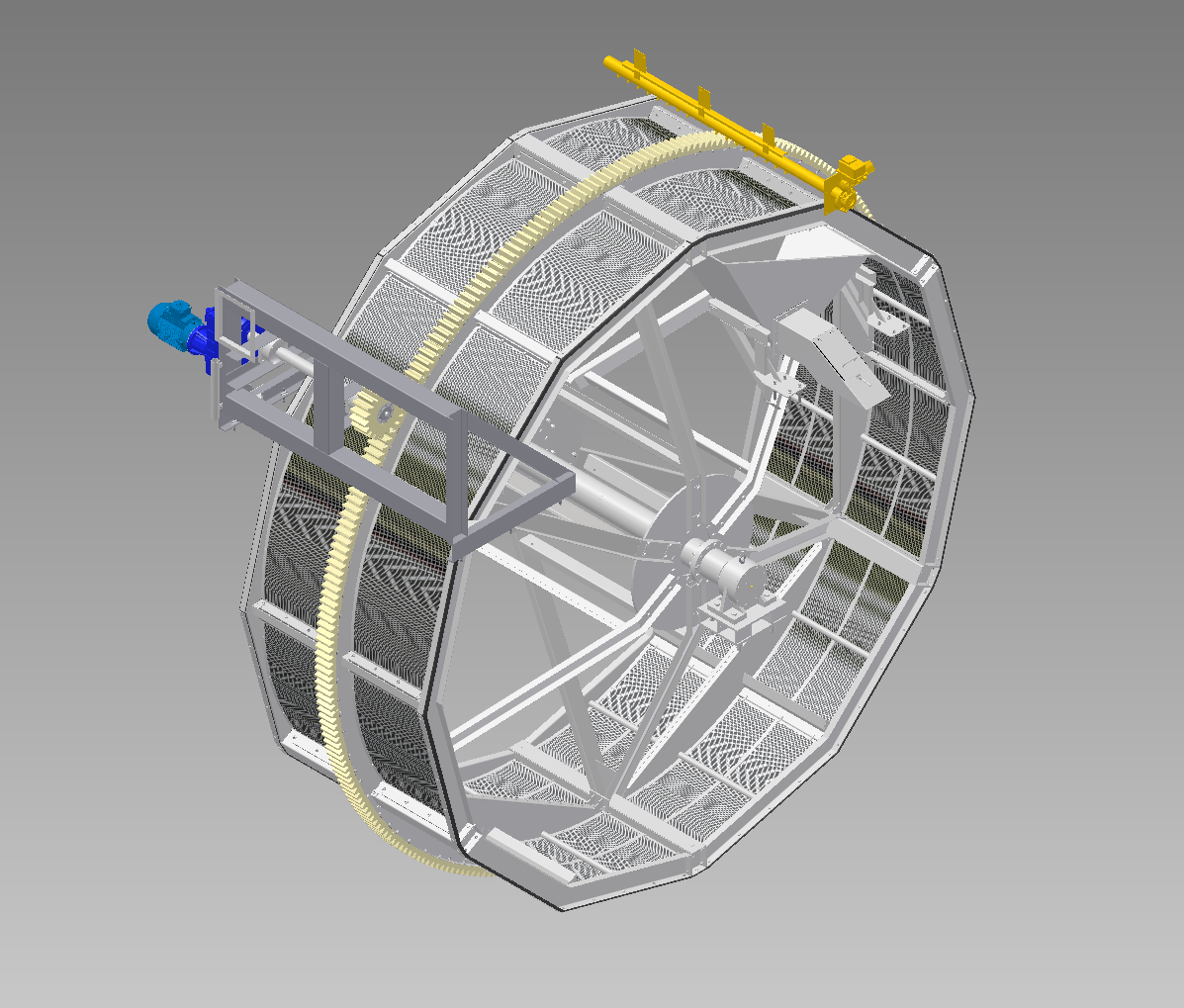

Rotary drum filters are a type of mechanical filter that use a rotating drum to remove solids from liquids. They are ideal for filtration applications in water intake systems, wastewater treatment, chemical manufacturing, and many other process industries. Rotary drum filters can handle a broad range of solids content, from fine suspensions to larger materials, and they are available in a range of sizes and configurations to suit specific process requirements.

Important components of rotary drum filters

As a leading provider of water intake systems, Hubert understands the importance of selecting the right components for a rotary drum filter. Some key components that are essential for optimal performance of the filter include magnesium carbonate, liquid separator tank, and scraper discharge.

Magnesium carbonate is an important filter aid that can improve the efficiency of the filtration process. Adding magnesium carbonate to the slurry helps to enhance the quality of the filter cake and reduce the number of contaminants in the filtrate.

The liquid separator tank is another crucial component of rotary drum filters. It is used to separate the filtrate from the slurry and is necessary for ensuring that the filtrate is of high quality. With a liquid separator tank, you can guarantee that the filtrate is free from any solid particles and meets the required quality standards.

The scraper discharge is a critical component used to remove the filter cake from the rotary drum. This helps to ensure that the filter cake is removed quickly and efficiently, allowing for continuous operation of the filter.

By selecting the right components for a rotary drum filter, including magnesium carbonate, a liquid separator tank, and a scraper discharge, it is possible to ensure that the filter is operating at peak efficiency and delivering high-quality filtration results. Hubert offers a wide range of components and solutions to help get the most out of a rotary drum filter. Contact us today to learn more.

Understanding the spray nozzles within rotary drum filters

Spray nozzles are an important component of rotary drum filters as they play a crucial role in the cake washing process. The nozzles are strategically placed to ensure efficient and uniform distribution of wash liquid across the cake surface. This ensures that the cake is effectively washed and the filtrate turbidity is minimized.

How do rotary drum filters work to achieve efficient filtration?

Rotary drum filters work by feeding a slurry of solids in suspension into a rotating drum with filter media. Belt discharge is a common type of discharge mechanism used for feeding the solid concentration slurry. The endless belt conveyors provide a reliable means of transporting filtered solids out of the drum and into the collection container. As the drum rotates, the solids form a layer of cake on the drum surface, while the liquid passes through the filter media and is collected in a vacuum receiver. A vacuum pump is used to create a vacuum pressure inside the drum, which helps to remove the moisture from the solids layer and enhance the filtration efficiency.

The solids layer is then discharged from the drum surface using a scraper blade or roll discharge, depending on the type of rotary vacuum filter. The solids are then collected and sent to disposal or further processing, while the filtrate is pumped out for further treatment or discharge.

Types of rotary drum filters

There are several rotary drum type filters available, each with its own unique features and benefits. Some of the most common types include:

- Rotary vacuum drum filters: A rotary vacuum filter is ideal for applications where high filtration rates, efficient cake washing, and low moisture content are required. They offer a high level of flexibility and can handle a wide range of solids content and particle sizes.

- String discharge filters: These filter drums use a series of parallel strings to support the filter media and provide efficient cake discharge. They are ideal for applications where a clear filtrate is required and the solids concentration is high.

- Roll discharge filters: These filters use a roll discharge mechanism to remove the solids layer from the drum surface. They are ideal for applications where a high level of mechanical wear resistance is required, such as for abrasive or gelatinous cakes.

Benefits of rotary drum filters in water and wastewater treatment

Rotary drum filters offer a range of benefits for water intake systems and wastewater treatment plants, including:

- High filtration performance: Rotary drum filters can achieve high filtration rates, with filtration efficiencies of up to 99.9% depending on the application.

- Low operating costs: The industrial filters have low energy consumption, require minimal maintenance, and have long operational life spans, resulting in lower operating costs over time.

- Wear resistance: Rotary drum filters are designed to withstand harsh environments and are available in durable materials such as carbon steel and stainless steel, offering excellent wear resistance. At Hubert, we understand the importance of selecting the right material for your filtration needs, and our team can provide expert guidance on the unique benefits of stainless steel.

- Effective cake washing: Rotary filters offer effective cake washing capabilities, which can help to minimize moisture content and improve the efficiency of downstream processes.

- Wide range of applications: Rotary drum filters can be used in a wide range of process industries, including food processing, pharmaceuticals and industrial water.

Process applications of rotary drum filters

Rotary drum filters are widely used in various process applications across different industries. They offer excellent filtration performance and are designed to handle a range of solids concentration slurries. Some of the most common process applications of rotary drum filters are discussed below:

- Wastewater treatment: Within the wastewater treatment plants are drum filters used for the removal of solids from the influent and effluent streams. They can handle a range of solids content and particle sizes, making them ideal for primary and tertiary treatment processes.

- Chemical manufacturing: Rotary drum vacuum filters are widely used in chemical manufacturing processes for the separation of solids from liquids. They are particularly effective for applications involving chemical pretreatment and chemical prep tanks.

- Pharmaceutical industries: The filters are commonly used in pharmaceutical applications and manufacturing processes for the separation of solids from liquids, including gelatinous cakes and abrasive slurries.

- Food processing: Rotary drum filters are widely used in the food processing industry for the separation of solids from liquids, including corn gluten and other food processing byproducts.

Key features of rotary drum filters

Rotary drum filters offer a range of features that make them an ideal choice for water intake systems and wastewater treatment plants, including:

- Rugged construction: Rotary drum filters are designed for heavy-duty use in harsh environments. They feature rugged construction and are available in a range of materials to provide excellent wear resistance and durability.

- Optimum range of solids concentration: Rotary drum filters can handle a wide range of solids content, making them ideal for applications with varying feed concentrations.

- Easy maintenance: Rotary drum filters require minimal maintenance and can be easily cleaned and maintained to ensure optimal performance.

- Versatile design: Rotary drum filters are available in a range of sizes and configurations to suit specific process requirements, making them ideal for a wide range of applications.

How to select a rotary drum filter?

Selecting the right rotary drum filter for your water and wastewater treatment needs can be a complex decision. When selecting a rotary drum filter, it’s important to consider a few key factors to ensure that the filter is optimized for your specific application.

Firstly, it’s important to consider the cleaning requirements of your application. Different applications require different levels of cleaning, and it’s important to select a rotary drum filter that can effectively remove the desired contaminants from the water.

Secondly, it’s important to consider the ideal filter cake for your application. The filter cake is the layer of solid particles that is removed from the water during the filtration process, and it plays a critical role in the overall effectiveness of the filter. It’s important to select a rotary drum filter that can consistently produce an ideal filter cake that is easy to remove and dispose of.

Another important factor to consider is mechanical pressure. The rotating filters can operate under either positive or negative pressure, depending on the specific needs of the application. It’s important to select a filter that can operate under the required mechanical pressure to ensure optimal performance.

In addition to the filter itself, it’s important to consider the integration with other components of the filtration system. This includes the slurry tank and slurry pumps, which are used to store and transport the solid concentration slurry produced during the filtration process. It’s important to ensure that the rotary drum filter is compatible with the slurry tank and pumps to ensure smooth operation of the entire filtration system.

Finally, it’s important to consider any unique requirements or constraints of your application. This can include factors such as space limitations or specific environmental conditions. By considering these factors, you can select a rotary drum filter that is optimized for your specific application and will provide efficient and effective filtration.

Maintenance and operational costs

Rotary drum filters are designed to offer low operating and maintenance costs compared to other filtration solutions. This is due to their ability to handle a wide range of solids concentration slurries, resulting in lower disposal costs. Additionally, their rugged construction and durability reduce the need for frequent repairs and replacements.

Conclusion

Rotary drum filters are an effective and reliable filtration solution for water intake systems and wastewater treatment plants. They offer high filtration performance, low operating costs, and excellent wear resistance, making them an ideal choice for a range of process industries. At Hubert, we are proud to offer a wide range of high-quality rotary drum filters to meet the needs of our customers. Contact us today to learn more about our range of products and custom solutions for your specific filtration requirements.