High-Spec Steel Assemblies

Complex machined welded constructions, assemblies, sub-assemblies and complete products

The High-Spec Steel Assemblies division forms a separate branch within Hubert, in which there is collaboration with a number of select parties.

Hubert has been supplying both components and assembled parts to the offshore industry and other applications within the shipping and dredging industry for many years. The market for fairground attractions is also interesting for Hubert given the heavy demands. Complex machined welding constructions, assemblies, sub-assemblies and complete products are part of our program.

For this market we work according to customer (mechanical) specifications. Our scope includes parts in single pieces, series as well as assembled products. Visit also our Dutch website staalbouwhubert.nl

Carbon steel & various exotic alloys

We process low-alloy and high-alloy carbon steel, fine-grained steel, stainless steel (various alloys), aluminum, cupronickel 90/10 and 70/30, alu bronze, monel, inconel, weldox, duplex, super duplex and Outokumpu 1.4835 (253MA). We can handle workpieces up to 40 (m)tons in our workshop.

Complex welding subject to international quality standards

We collaborate with international recognized notified bodies. The products we manufactre must always comply with internationally recognized quality standards. Hubert has a wide experience with for example following standards:

• Welders qualified acc. EN 9606-1/ASME IX/AWS D1.1

• Welding procedures qualifications acc. EN 15614/ASME IX/AWS D1.1

• Welding qualifications for various materials

We collaborate with international recognized Notified bodies like German T.U.V., Lloyds, Det Norske Veritas, Bureau Veritas, ABS, etc.

Platforms

Platforms for (nuclear) power plants

Hubert manufactures major components like platforms for industrial installations in aggressive environments. Materials applied are stainless steel and duplex.

Containers

Containers for industrial applications

Hubert manufactures major components like custom designed containers for industrial installations. Materials applied are stainless steel and duplex.

Steel Production

Components for steel production plants

Hubert supplies heat-resistant hoods applied in heat treatment processes in steel production plants (material Outokumpu 1.4835 -253MA).

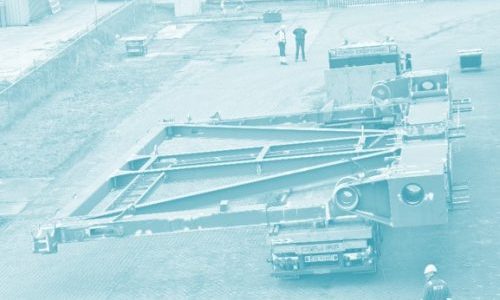

Pipelay Vessels

Hoisting installations – piplay vessels

Hubert manufactures major components for pipelay vessels, used to construct submarine pipelines.

Heavy lift vessels

Hoisting installations – heavy lift vessels

Hubert manufactures also hoisting booms for heavy lift vessels like floating sheerlegs with a crane.

Knuckle beams

Hoisting installations – knuckle beams

Hoisting installations also have many critical components. Hubert, for example, supplies knuckle beams for cranes. These products are also thoroughly tested before they are put into operation.

Hoisting beams

Hoisting installations – beams

Crane components like hoisting beams are also provided with adjacent constructions like platforms and stairs.

Pedestal

Hoisting installations – pedestal

Hubert manufactures substructures for cranes on ships like pedestals.

NDT tests

Hoisting installations – NDT tests

Crane components like hoisting beams are tested according international standards, including Non-Destructive Testing (NDT).

Leisure attractions

Components for leisure attractions

Hubert supplies critical components for fairground attractions. These products must also meet stringent requirements.

Customer Stories

Project: Replacement of gutter and clearing bridge settling tank at WWTP Birdaard

The elaboration of the drawings with accompanying calculations in the preparation phase were well worked out. The construction of the new gutter and bridge was installed satisfactorily by employees and especially the foreman. The project was completed on time, both financially and in the delivery of product certificates and revision. A great project and end result was achieved through synergy between client and contractor.

Wetterskip Fryslan, Netherlands, mr. R.T. van der Zee, Design coordinator - Director