Case Study

BAPCO / JGC Gulf International

HLPH Facility – Refinery / Seawater Intake Filtration System

Bahrain

Project introduction

Hubert was awarded the contract from JGC Gulf International Co. Ltd. for the Bahrain Petroleum Company (BAPCO) to improve the seawater filtration system at their HLPH facility. This sea water intake system had to be delivered including all complementary equipment, items and services to meet the design and environmental conditions. Hubert was responsible for ensuring that the specification was met for all deliveries and services in subcontracting.

Hubert Supply

The seawater intake filtration system is designed to remove completely sea grass / weed, debris, plastic bags, wood chip, mollusk, jelly fish etc. The system consist of sluice gates positioned upstream and downstream of a Hubert bar screen and travelling band screen. Motorized Hubert sluice gates are used for drying the channel of each intake ’train’ to give access for maintenance of both bar screens and travelling band screen.

Hubert bar screens were used to keep out large parts. Our screens are designed to prevent vibrations during all operating conditions. They are therefore rigidly mounted on supporting profiles. Bar screens will be periodic cleaned by an automatic raking system, placed on a monorail construction just downstream of the inlet sluice gates. Two (1 working / 1 stand-by) trash raking systems are included for a full screening function.

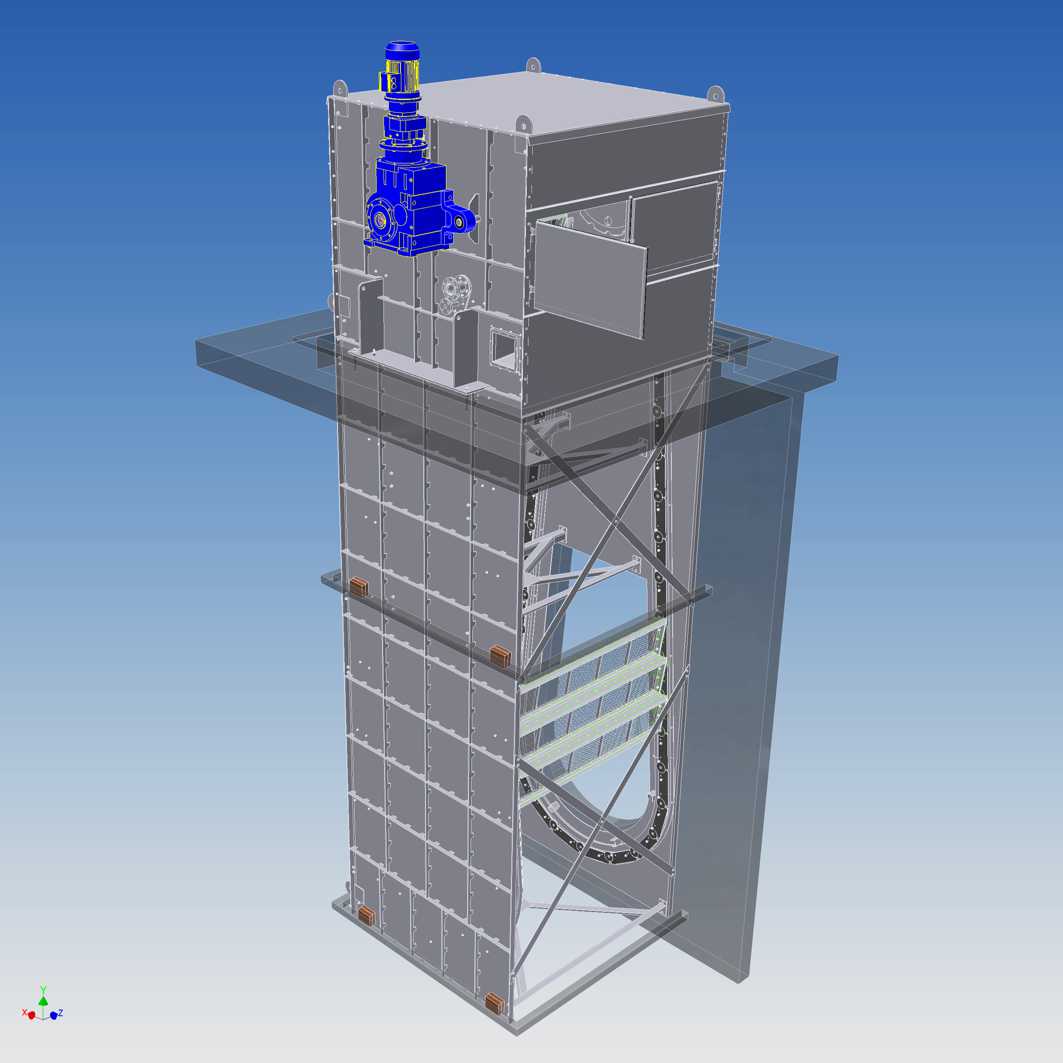

The installation is provided with Hubert travelling band screens based on a dual flow design. This will mean that water will flow from the outside of the screen through the mesh panels to the inside of the screen and then out through an opening in the back civil work wall of the screen chamber. The debris, which is collected on the outside of the mesh will be lifted above deck level, where it will be removed by high pressure water spray and then disposed.

Key Figures

- Location: Bahrain

- Hubert products: sluice gates, coarse / bar screens & automated raking system, travelling band screens

- Materials: duplex, (coated) steel & stainless steel 316L

- Year: 2018-2019