Travelling Band Screen

A Hubert water intake travelling band screen is also called ’travelling water screen’

A travelling band screen or traveling water screen is a self-cleaning fully automatic screen suitable to filter large flow rates in a water intake at a relatively fine filtration degree as a secondary step.

Every project intake location is different. Excavating and civil engineering cost vary from site to site and have a important influence on the choice of screening system, where the choice is often made between a travelling band screen or a drum screen.

We supply our own designs where possible, however all systems are engineered as per your project specifications. If you prefer a different design, we can of course also supply this. We are happy to advise you to make the best choice and flow pattern for your project. When renovating existing installations (which have been in operation for many years), (dated) designs are often used or, if possible, the civil construction is adapted to a modern design.

Water Intake Systems

Our specialisation: water intake systems for cooling, drinking and process water

We are specialised in water intake systems for cooling, drinking and process water. These systems can be found in power stations, petrochemical plants and refineries, desalination plants, drinking water and irrigation plants and industrial production plants requiring a huge demand of process water.

We supply complete complete ‘screening trains’ including all additional equipment, like controls and cathodic protection. This movie includes an animation of a typical water intake, showing the water flow from the suction from the sea to the arrival at the pumps.

You will find our projects in both new construction (EPC) projects and renovation and optimization of existing water intakes.

Travelling Band or Water Screen

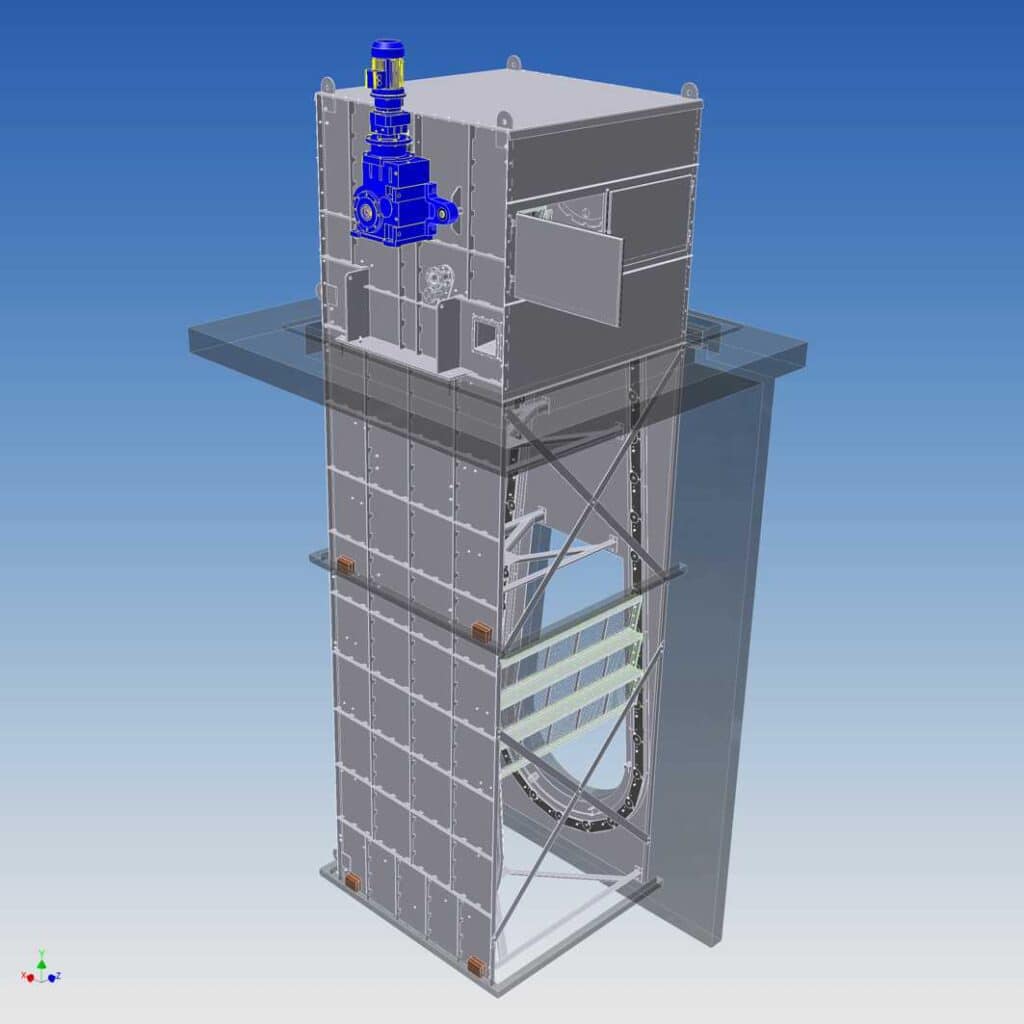

A Hubert travelling band screen has a compact design

The Hubert travelling band screen is the ‘heart’ of the ‘screening train’, often used used for (sea)water intakes as part of power plants and desalination plants, where big tidal differences can also play a role. It is more compact than a vertical drum screen, but it has still a high capacity. Quite common flow rates are 15.000 m3/h per screen, depending on customer requirements and the local situation at the intake. Today, a lot of duplex and super duplex (PREN > 40) is used for screens.

A travelling band screen is typically installed in water intake systems downstream from coarse bar screens.

Woven mesh with a diameter of about 2-10 mm is used as relative fine filter medium.

Design, Construction and Operation

Hubert travelling band screens require only a small installation area due to the vertical construction. This type of screen is used in places where the construction area of the total cleaning installation is limited or where big differences occur between water levels.

The band water screen operates on a conveyor belt principle. The ‘conveyor belt’ is composed of mesh panels which are mounted between two endless heavy duty transport chains. The chains are driven by 2 sprockets.

The debris, trapped on the screens is removed by spray water jets and discharged through a flushed chute. The drive unit, flushing mechanism and debris hopper are located at deck level. The upper section above decl level is fitted with a metal or reinforced polyester composite cover.

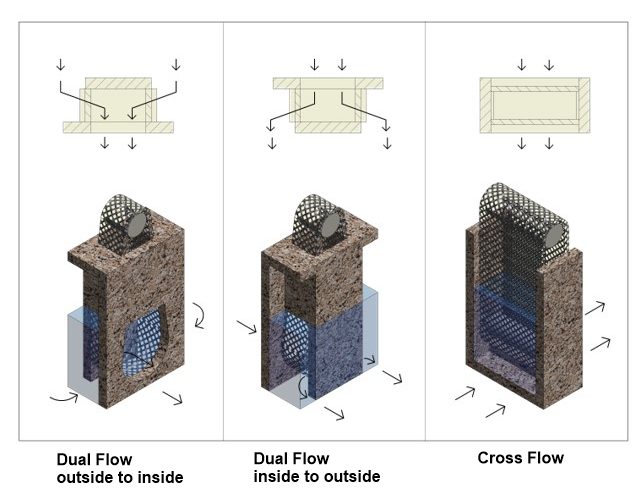

Hubert traveling band sceens are available for different flow patterns.

Special designs can be provided with facilities for removing and discharging other debris like jellyfish and seawead. If this is not or insufficiently covered by the coarse screens in front of the screening system.

Skid or Embedded Configuration

Hubert travelling band screens can be configurated as a skid, which minimizes on-site mounting. The band screen can also be part of the civil construction and assembled on site (embedded).

Features and Benefits

- Large flow capacity

- No debris carryover

- High screening efficiency (99%)

- Minimal construction space required

- Big tidal differences

- High quality and reliable

- Maintenance free

- Long lifetime (30 years or more)

- Resistant to abrasive water

- (Sea) water lubricated bearing

- Heavy duty chains

Fish Friendly – Fish Recovery System

Hubert’s traveling band screens can be supplied with a fish recovery gutter or channel that allows trapped fish to be removed in a gentle and effective way. These recovery systems are tailor-made for each project. See also this movie.

Standard Dimensions and Materials

- Width up to 4 m

- Pit depth up to 20 m

- Mesh opening 2/ 10 mm

- Materials can be (partly) coated carbon steel, stainless steel, duplex and super duplex (PREN > 40)

Travelling band screen: different flow patterns

Hubert supplies all common applied flow patterns, depending on a number of things including channel width / available space, etc. Cross flow or Thru-flow screens are relative expensive when large mesh areas are required. Dual-flow screens perform better than thru-flow screens. They are smaller and have more capacity with same mesh surface. Please contact us for advice!

Customer Stories

Project: Replacement of gutter and clearing bridge settling tank at WWTP Birdaard

The elaboration of the drawings with accompanying calculations in the preparation phase were well worked out. The construction of the new gutter and bridge was installed satisfactorily by employees and especially the foreman. The project was completed on time, both financially and in the delivery of product certificates and revision. A great project and end result was achieved through synergy between client and contractor.

Wetterskip Fryslan, Netherlands, mr. R.T. van der Zee, Design coordinator – Director