Micro Screen

Micro screen: widely applicable for fine-filtration of large water flows

A Hubert micro screen or horizontal rotary micro strainer can be used for pre-treatment of influent and effluent in a waste water treatment plant.

More efficient reuse of wastewater from municipal wastewater treatment plants or industrial production processes, make use of these filters increasingly interesting. Think of the recovery of useful raw materials from waste water or process water, such as cellulose fibers, but also stricter discharge requirements.

Our micro screens are custom engineered in which the customer plays a major role in achieving the correct efficiency, as the customer usually has the most experience with his process.

Other applications can be found in (fresh) water intakes, acting as (fine) pre-filtration system being part of potable water production plants or production plants that consume a lot of process water. See also Water Intake Systems / Drum screen.

Our definition of horizontal drum screen implies that debris is discharged through the main shaft and the filter lies in an enclosed pit or tank.

For drinking water company Dunea, Hubert succesfully removed mussel seeds with micro screens. The full article can be read here.

General information about waste water treatment can be found on Wikipedia.

Hubert – Waste Water Treatment

High quality equipment with a very long lifetime

Hubert supplies high quality installations and sub-installations applied in municipal and industrial waste water treatment plants. Our installations are of high quality and offer a long service life. In addition to the micro screens shown on this page, we also offer also a selection of our coarse screens to the waste water treatment market.

We are active in both new construction (EPC) projects and renovation and optimization of existing water intakes.

Hubert – Waste Water Treatment

High quality equipment with a very long lifetime

Hubert supplies high quality installations and sub-installations applied in municipal and industrial waste water treatment plants. Our installations are of high quality and offer a long service life. In addition to the micro screens shown on this page, we also offer also a selection of our coarse screens to the waste water treatment market.

We are active in both new construction (EPC) projects and renovation and optimization of existing water intakes.

Micro screen or Micro Strainer

A Hubert micro screen or micro strainer is used for filtration of large water flows

Flow rates can be up to 5000 m3/h per screen, depending on customer requirements and application. Woven fabric or mesh with a diameter of about 11 up to 500 micron is used as filter medium. This type of filter is usually used under free fall conditions. It is called micro screen because the filtration degree is less than 1 mm. The efficiency and capacity of a micro strainer depends on several factors including the characteristics of the fine filtration mesh (fabric), rotation speed of the micro screen, the quality of the water to be purified and the amount of backwashing water.

We also use perforated plate as filter medium, with a hole dia starting from 0.5~1 mm. In that case we call this type of filter a perforated (rotating) drum screen. Larger filtrations (> 1-2 mm) will be normally done by travelling band screens or larger vertical drum screens in open channels (water intake systems).

Micro Screen or Micro Strainer

A Hubert micro screen or micro strainer is used for filtration of large water flows

Flow rates can be up to 5000 m3/h per screen, depending on customer requirements and application. Woven fabric or mesh with a diameter of about 11 up to 500 micron is used as filter medium. This type of filter is usually used under free fall conditions. It is called micro screen because the filtration degree is less than 1 mm. The efficiency and capacity of a microstrainer depends on several factors including the characteristics of the fine filtration mesh (fabric), rotation speed of the microscreen, the quality of the water to be purified and the amount of backwashing water.

We also use perforated plate as filter medium, with a hole dia starting from 0.5~1 mm. In that case we call this type of filter a perforated (rotating) drum screen. Larger filtrations (> 1-2 mm) will be normally done by travelling band screens or larger vertical drum screens in open channels (water intake systems).

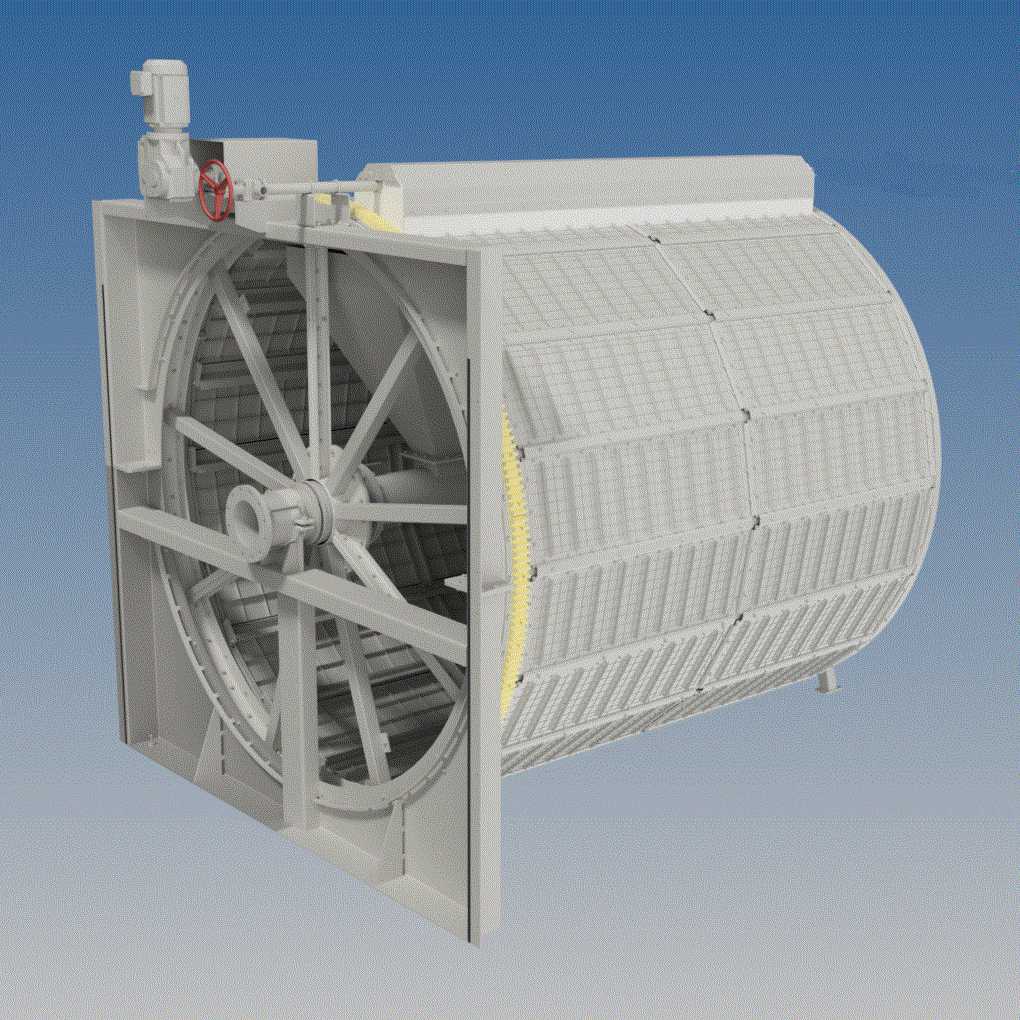

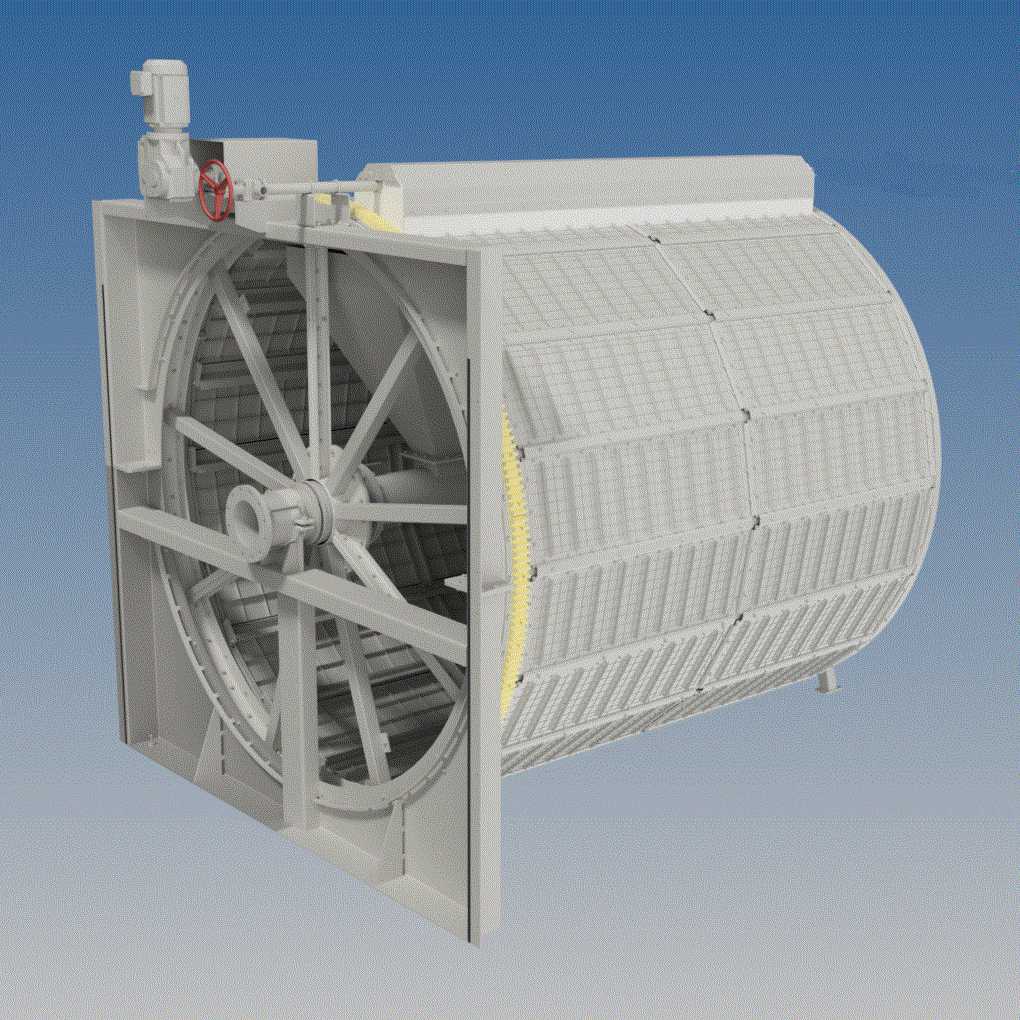

Design, Construction and Operation

The Hubert micro screen system consist of a drum fitted along its outer circumference with screen panels. The drum is placed in a concrete pit or tanks and rotates on a stationary hollow shaft fitted with one or more funnel-shaped debris collectors. The feedstock of water enters the drum axially and flows radially through the mesh panels. The dirt particles remain trapped in the mesh.

As the drum rotates the row of sceen panels pass under a set of high pressure water jets at the top of the drum. The dirt particles are washed from the screen and discharged through the funnel-shaped debris collectors and the hollow shaft.

The “clean” side of the screen compartiment is fitted with an overflow weir which enables the water inside the screening chamber to be kept at a constant level. This ensures that the largest possible screening area is constantly submerged resulting in a high yield of solids.

Features and Benefits

- Filtration range 11-500 micron

- Light, stable and robust construction

- Reliable

- Maintenance free

- Long lifetime (30 years or more)

- Resistant to abrasive water

Standard Dimensions and Materials

- Drum length up to 6 m

- Drum diameter from 0,7 up to 3,5 m

- Mesh opening from 11 to 500 micron

- Materials can be stainless steel and exotic alloys (a variety of (super) duplex grades)

Micro Screen Explanation

This video explains how a micro screen works. This is a micro screen specially made for a pilot project to test two different mesh widths for pre-filtration at a plant.