Hubert damwanden

Op maat gemaakte systemen voor het veilig afsluiten van en droogzetten van waterinlaten.

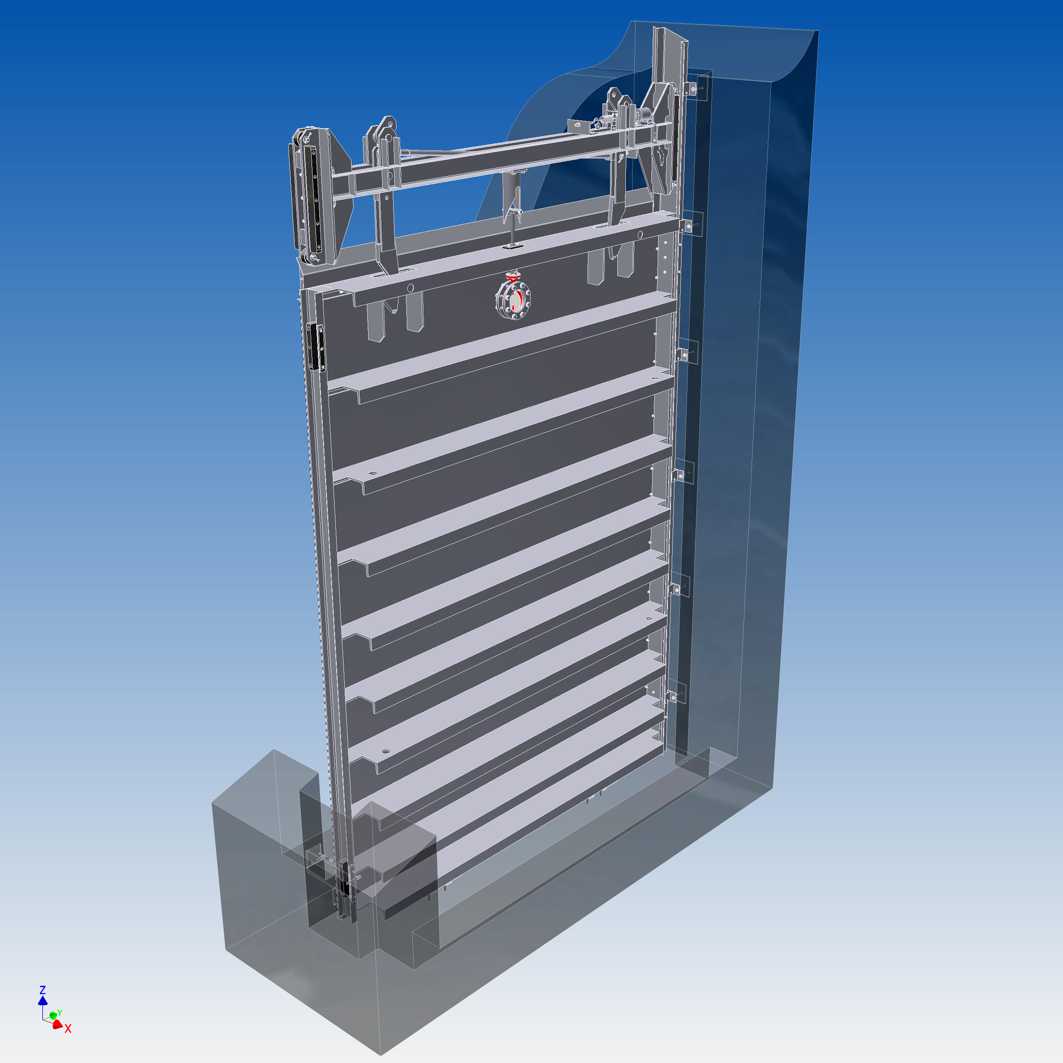

Onze damwanden bieden een betrouwbare en snelle manier om grote inlaatkanalen, pompkamers en waterwegen droog te zetten voor inspectie, onderhoud of renovatie. Elk systeem wordt volledig op maat ontworpen op basis van projectspecificaties en hydraulische eisen.

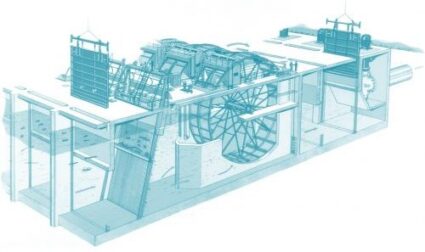

Deze damwanden worden doorgaans geplaatst aan de instroomzijde van waterinname-installaties, vóór de grofroosters, trommelfilters of bandschermen.

Door het gebruik van damwanden kan een afzonderlijk deel van het kanaal worden drooggezet, zodat onderhoud aan pompen of filtersystemen veilig en efficiënt kan worden uitgevoerd..

Functies

Onze damwanden worden volledig op maat ontworpen om de waterdruk in elke specifieke situatie aan te kunnen. Bij diepere watergangen worden ze uitgevoerd in twee of meer secties. De afdichtingen zijn gemonteerd op de vlakke zijde van de damwanden en zorgen, samen met de in de betonnen kanaalwanden geïnstalleerde geleiders, voor een optimale afdichting en probleemloze installatie.

Voor extra gebruiksgemak kunnen de systemen worden aangevuld met een optioneel opslagframe en kathodische bescherming, zodat zowel de levensduur als de betrouwbaarheid van de installatie verder worden vergroot.

Dankzij deze doordachte constructie en hoogwaardige materialen functioneren de damwanden onder alle omstandigheden veilig, robuust en onderhoudsvriendelijk; een essentieel onderdeel van elke moderne waterinlaatinstallatie.

Voordelen

- Snelle en veilige afsluiting van waterinlaten

- Volledig op maat ontworpen

- Optimale afdichting en probleemloze bediening

- Geschikt voor extreme en zware omstandigheden

- Modulair en flexibel inzetbaar

- Automatische bediening

Downloads